How AI is revolutionalizing global supply chain management

Here's What We've Covered!

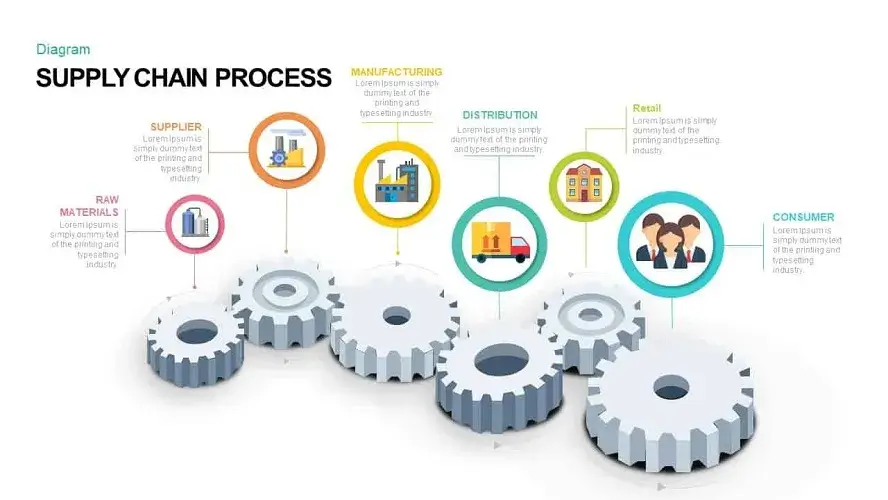

The global supply chain and logistics are undergoing a phase of evolution. Artificial Intelligence (AI), Machine Learning, Robotics and many of the disruptive technologies have changed the way the global supply chain works. As a result, the practices in logistics have become more innovative, efficient and progressive. The supply chain is one area that has inherent complexities. Areas such as inventory, choice of carrier, logistics personnel, cost-maintenance, warehousing, etc. require astute decision-making.

As companies have humongous data related to logistics and supply chain, they are now keen on employing analytics for predictive decision-making. There is an increased requirement of efficient and advanced tools that can accentuate the level of logistics and supply chain management. The aim is to have a more data-driven, autonomous and optimized supply chain.

Here are five ways in which AI can positively impact the Global Supply Chain:

(1) Improving Overall Performance

AI is a disruptive technology that brings together various forms of learning, supervised, and unsupervised. With the help of both these forms of learning, AI can detect the issues in the company’s operational structure, analyze the supply chain performance and adopt a four-pronged approach. To reduce the areas that lower performance, increase those which enhance the functionality, ensure compliance and finally ensure timely delivery of goods.

Use Cases: Simplified Custom Clearance

UK has a system, Customs Freight Simplified Procedures (CFSP) that allows faster clearance of goods from countries outside Europe. This is primarily required for perishable goods. This system uses a blend of AI and Blockchain to simplify the customs process. The underlying technology can also be used in other areas of logistics management.

(2) Forecasting Demand

Demand forecasting is an integral part of Supply chain management. There is a lot of data available for studying the demand patterns. The flow of sales, the geographical navigation, the trajectory of the deliveries help an organization to understand the trends in demand. AI can use the data to forecast demand and plan for logistics to minimize wastages and losses.

Use Case: Steel Industry

Research by Malaysia Institute of Supply Chain Innovation (MISI) elucidated the point. In the time span between 2012 and 2017, it chose to predict demand forecast for steel manufacturers. Instead of traditional methods, it employed ARIMAX and Neural Networks (NN) to forecast demand. Unlike traditional methods, the AI methods could work on unlimited causal factors and also continuously refine the predictions based on available data for accurate results.

(3) Better customer experience

The primary goal of supply chain management is to ensure the timely delivery of goods to end-users. AI can greatly be used to monitor the level of customer satisfaction and personalization. Companies can offer a bot service to oversee if the goods are delivered to the customers timely. They can also be used immensely to address customer queries and build lasting relationships with them.

Use Case: Chatbot-enabled customer query resolution

The e-commerce sector thrives on customer relationships. Real-time human-interaction, 24/7 query resolution and live updates about the transit of goods go a long way in ensuring optimal delivery service. We all have experienced this at some point while ordering through Amazon, Flipkart, Big Basket or other e-commerce platforms. Similarly, Procuebots can also be used to speak to suppliers to negotiate better terms.

(4) Minimize Transportation Risks

One of the critical areas of logistics is the safe transportation of goods. In transportation, there is a lot of scope for manual errors, traffic rules, and accidents. AI can provide a lot of solutions to answer these. These solutions can be effectively deployed to ensure the best traffic arrangements, consider maximum safety and reduce wastages that may happen in accidents. Companies are increasingly deploying AI and Machine Learning to avoid any kind of such untoward incidents, or else they result in huge cost overruns.

Use Case: AI-based transport deployment

You book an Ola or Uber on your mobile app and you immediately get notifications of price and estimated ride cost. Not just that during your ride you are able to see the best possible route and plan your journey accordingly. There is also an option to raise an alarm in case of emergencies. This is AI at work. Toyota, KDDI, Accenture, and Japan Taxi have collaborated to develop a taxi deployment service to predict vehicle demand. Even for goods transportations, such kind of system can help in predicting the availability of vehicles, knowing the optimal route, minimize accidents. Autonomous vehicles that are already in the formulation stage in the US are a futuristic attempt to deploy AI in logistics transportation.

(5) Efficient and quicker sorting of goods

Sorting of goods can be one of the most cumbersome and time-consuming processes when it comes to logistics. A lot of costs also go into employing people only for sorting and packaging the goods. The larger the company’s operations, the more is the time and costs that go into the process. Not only does it leads to high costs, but it could also lead to a delay in deliveries. AI-Based solutions for efficient sorting and packaging is a boon, especially in peak times.

Use Case: Blue dart employs IntelliSort

Plagued by sorting challenges, Blue Dart joined forces with Locus who deployed its automated sorting solution. This proprietary solution called IntelliSort lowered the time-spent on sorting and the company could ship the goods faster. It also enhanced route-mapping accuracy and resulted in huge cost optimization for Blue Dart.

Read more: Impact of Data Science on Retail Industry

Resent Post

>

Best Study Abroad Courses for Commerce Graduates

>

Emerging commerce career options in India (2026): From CA to Data Analyst

>

ACCA Opportunities You Didn’t Know About – Think Beyond Audit!

>

Which Courses After 12th Commerce With High Salary Are in Demand Worldwide?

>

How to Find ACCA Jobs Online After Qualifying: Real Portals, Tips & Career Guidance

Follow Us For All Updates!